How Much Ink and Pretreat Do I Need?

Ruby Dann

DTG is subjective. You and your competitor have completely different standards of what can be sold to a customer and different methods for getting that sale-worthy print. This can make it difficult for new printers to know how much ink or pretreat they need. FIREBIRD is here to help with that.

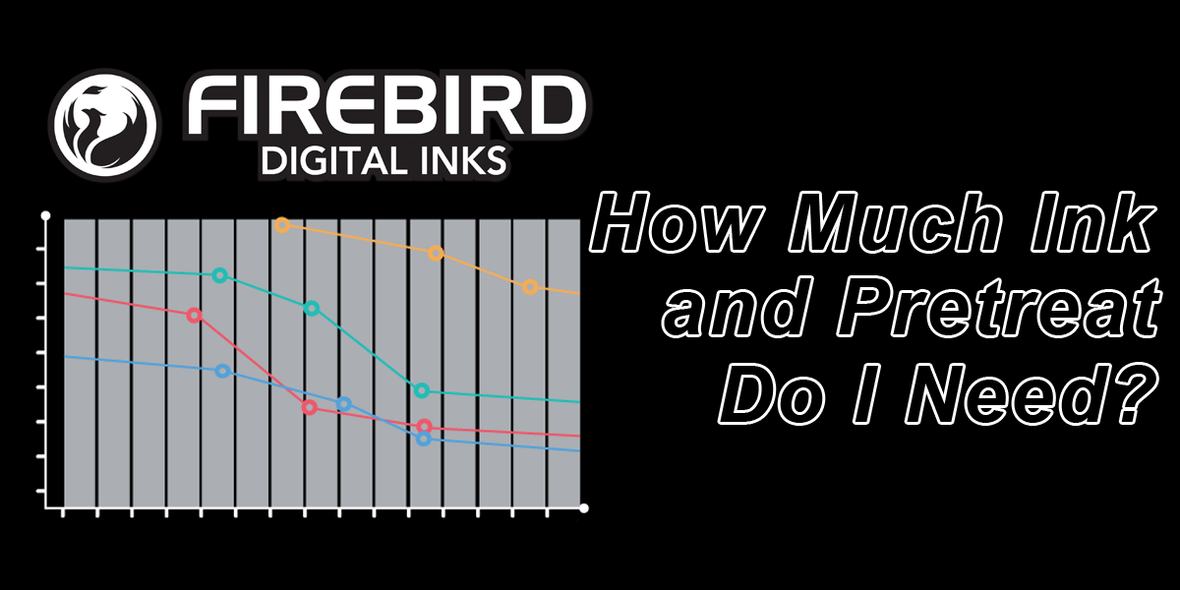

The below chart offers a rough guideline on the pretreat vs ink ratios that you can expect while printing. With this in mind, we at FIREBIRD want to highlight a few key points.

1. Fabric Matters

Quality prints are tougher to get on certain shirts. You’ll notice on our graph that ringspun garments consistently need less ink than cheaper carded cotton. Veteran printers are well aware of this and adjust their print settings for lower quality shirts. Meanwhile, heavy blended sweatshirts require more ink and pretreat than any tee.

2. Watch Your Pretreat/Ink Ratio

Novice printers often don’t understand what makes one print better than the next. Each line on our chart has three points highlighted for the best targets. The first point on the left is where you will see a passable print. The farthest right point represents your best cost ratio.

If you go too far left you’ll encounter fibrillation, ink bleeding, and distressed prints. Further right, adding more pretreat isn’t worth the added cost for what it saves in ink. You’ll also see scorching, washout, and stiff fabric if you push to an extreme.

3. Do Your Own Tests

FIREBIRD does what we can to give our customers a place to start. This graph and our T-Shirt Matrix should both help figure out your best settings. However, these are only starting points. Not every shirt is covered by our Matrix and you might find an exception to the rules that we’ve listed here.

This is why you should always test before trying something new. We recommend following our guide on Performing Your Own Pretreatment Tests to help figure out the settings that fit your shop. You can also feel free to give us a call at 203-306-2988 or email ink@firebirdink.com for hands on advice.